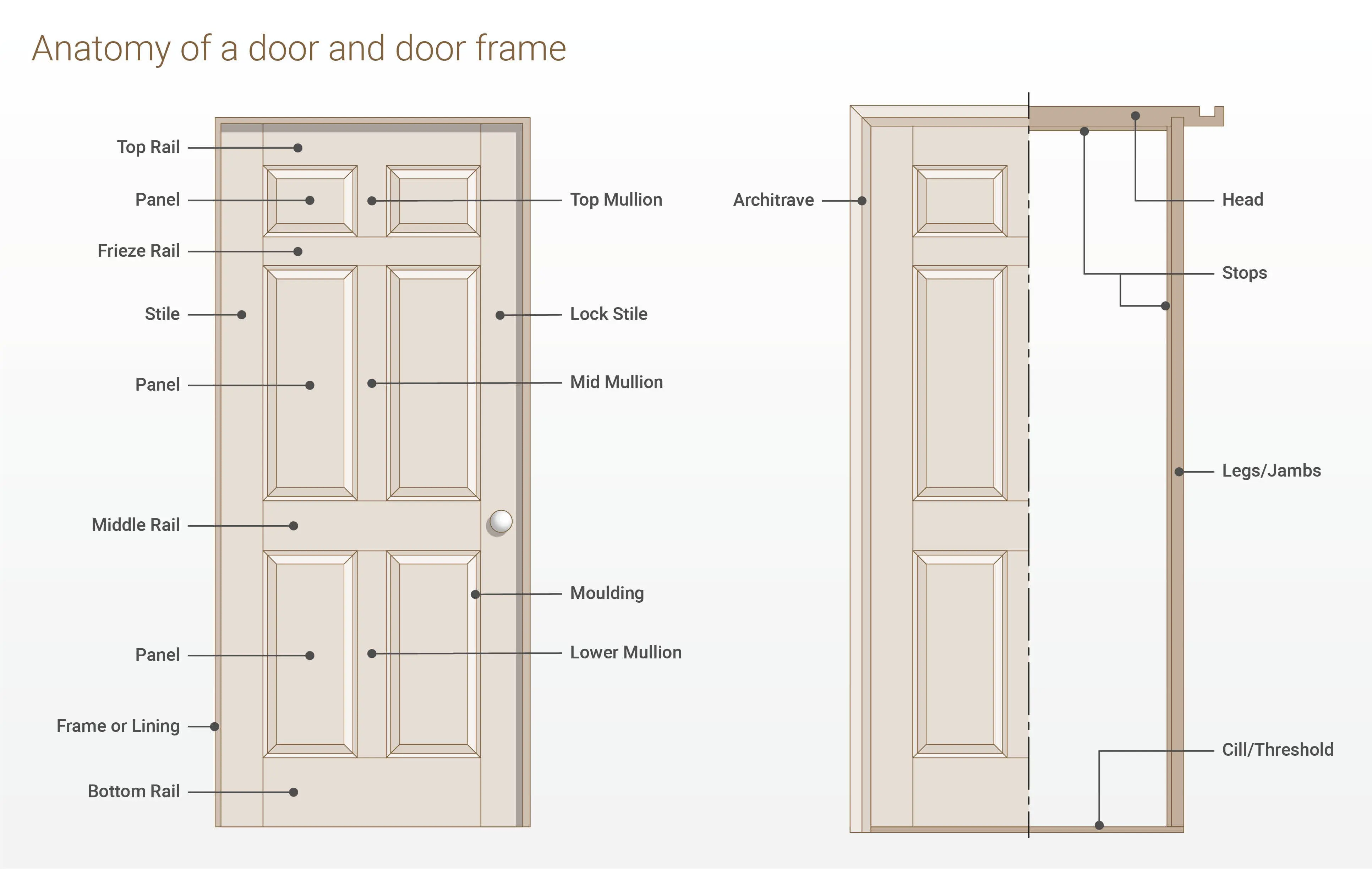

A jamb, in architecture, is the side-post or lining of a doorway or other aperture. The jambs of a window outside the frame are called “reveals.” Small shafts to doors and windows with caps and bases are known as “jamb-shafts”; when in the inside arris of the jamb of a window they are sometimes called "scoinsons."

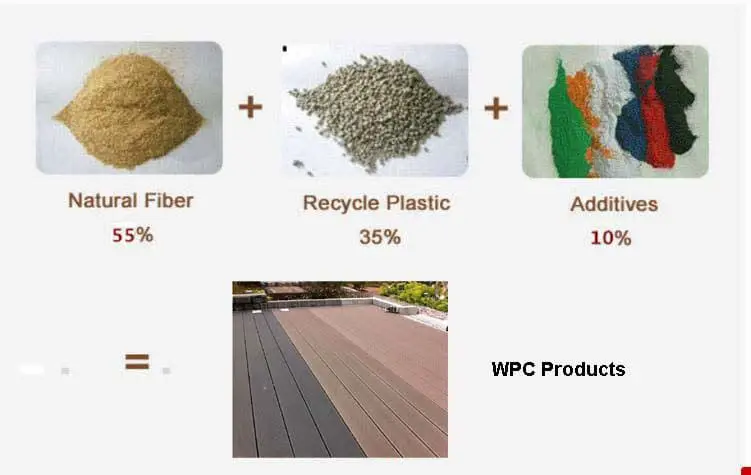

Wood-plastic composites are composite materials made of wood fiber/wood flour and thermoplastic such as PE, PP, PVC, or PLA. In addition to wood fiber and plastic, WPCs can also contain other ligno-cellulosic and/or inorganic filler materials.

WPC also known as Greenwood is new age product which combines the properties of wood and plastic offering a highly durable material. Find our product features below.

| Product Name | WPC Capped Co-Extrusion WPC Decking | Main Material | 80% PVC, 20% Wood additives |

| Color | White, Primed or customized | Surface | Smooth or Woodgrain |

| Size | 7ft, 8ft, 10ft, 12ft or customized | Package | Pallet with film |

| Items | wpc door jamb/wpc door brick mould/wpc door mull post/wpc door astragal | ||

| Usage | Exterior and interior | ||

| DRAWING | DESCRIPTION | DIMENSION(mm) | FINISH |

|---|---|---|---|

|

3.5" Astragla | 32x116 | Smooth / Embossed |

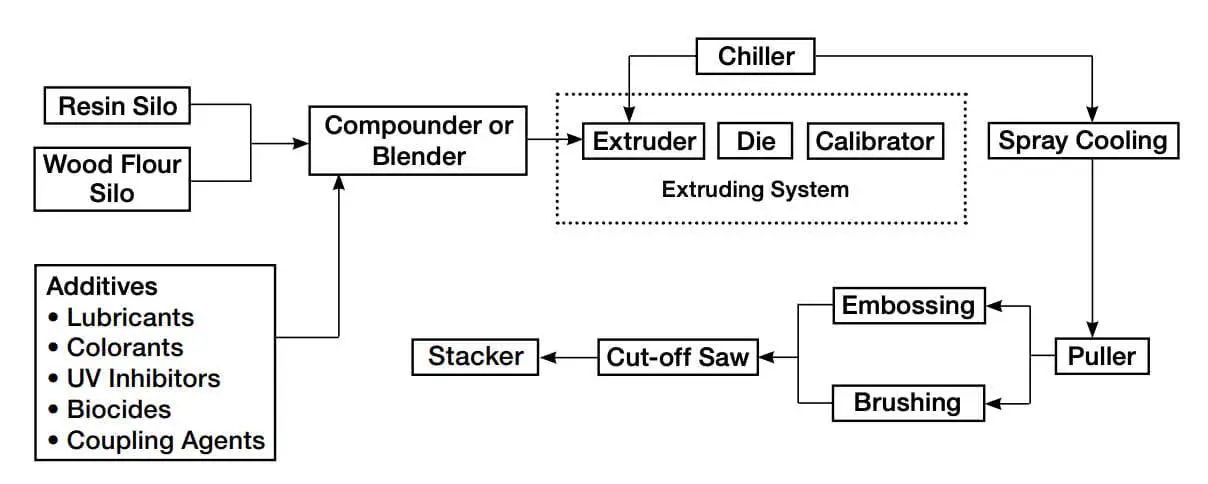

Wood-plastic composites (WPCs) are produced by thoroughly mixing ground wood particles and heated thermoplastic resin. The most common method of production is to extrude the material into the desired shape, though injection molding is also used.

Wood Plastic Composite (WPC) is a composite material made from sawdust and plastic as polymer bonding, that used in a variety of structural and non-structural applications. Nowadays, In Indonesia WPC is made from Sengon sawdust and recycled HDPE plastic. This research was conducted in order to investigate the physical and mechanical properties of WPC from Sengon sawdust in accordance with ASTM D7031. From the physical test, due to its water restrains, WPC has low moisture content, water absorption and swelling. For the mechanical properties, the bending strength and shear strength are around 40.49 MPa and 27.35 MPa, respectively. However, the WPC tensile strength is lower than common tropical wood, which is only 5.54 to 12.75 MPa, due to the absence of grain in WPC. Furthermore, the modulus of elasticity is only 2113 to 3398 MPa or around one tenth of that wood or concrete modulus of elasticity. From the withdrawal test shows that sheet metal screw type has the highest withdrawal strength compared to cut thread wood, and fine thread drywall screw. Hence, for structural application it is suggested that the WPC board is used for structural element with high moment inertia such as shear wall as its lower modulus of elasticity but has high shear strength.

For Furthur Questions

Talk To Our Professional Engineers